Valve Runout Comparator Gauge

March 21, 2022

Two Point attachment for small bore

March 21, 2022Roller Runout Comparator Gauge

Function

It is used to check the dimensions of two-point and three-point taper rollers and needle rollers.

This equipment ensures accurate measurement and comparison of critical dimensions, including diameter, taper angles, and geometric tolerances.

It is essential for quality control in manufacturing processes, particularly in the automotive and bearing industries.

Other Similar Products

-

Details

Three Dial Comparator

Function

It is used for dimensional measurements of components such as flange height, track width, and total height of bearings.

It also measures cylindrical or hollow components, including bushes.

This equipment ensures precise evaluation of critical dimensions in various mechanical parts.

Range Table :

MODEL NO. GT-300 BASE PLATE SIZE 200 X 300 MM BASE PLATE HARDNESS 58-62 Hrc -

Details

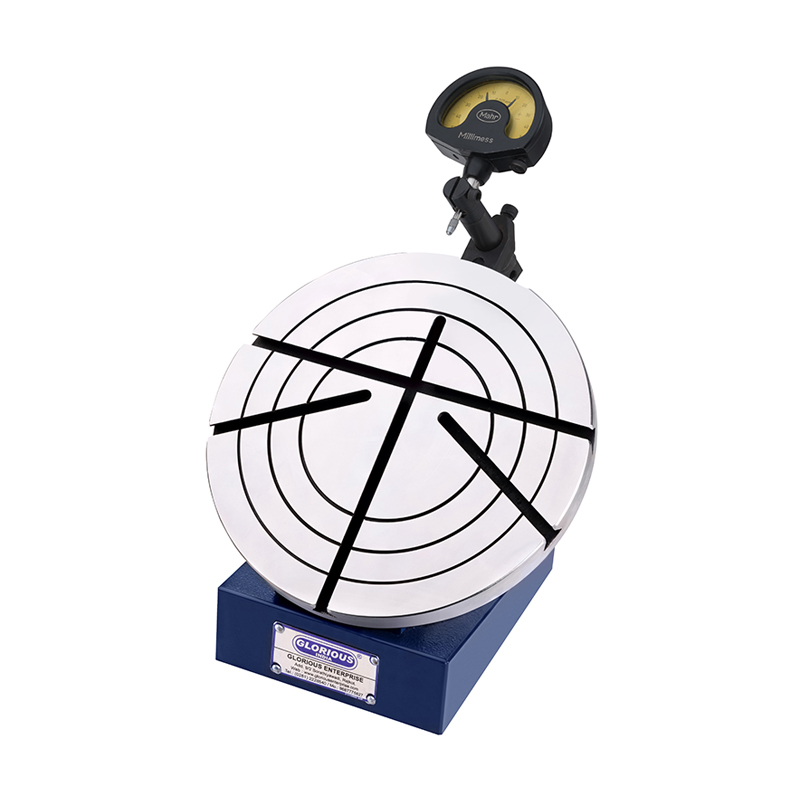

OD Comparator

An OD Comparator is employed for the precise evaluation and comparison of the Outside Diameter (OD) of components.

It facilitates the assessment of ovality and squareness to end faces using both 2-point (90˚) and 3-point (120˚) methodologies.

This equipment finds extensive application in the automotive and bearing sectors, ensuring dimensional accuracy and compliance with rigorous quality standards in manufacturing processes.

RANGE TABLE:

MODEL NO GD-200 GD-250 GD-300 GD-400 GD500 BASE PLATE DIAMETER 200 MM 250 MM 300 MM 400 MM 500 MM OUTER DIAMETER RANGE 180 MM 230 MM 280 MM 380 MM 465 MM BASE PLATE HARDNESS 58-62 Hrc 58-62 Hrc 58-62 Hrc 58-62 Hrc 58-62 Hrc -

Details

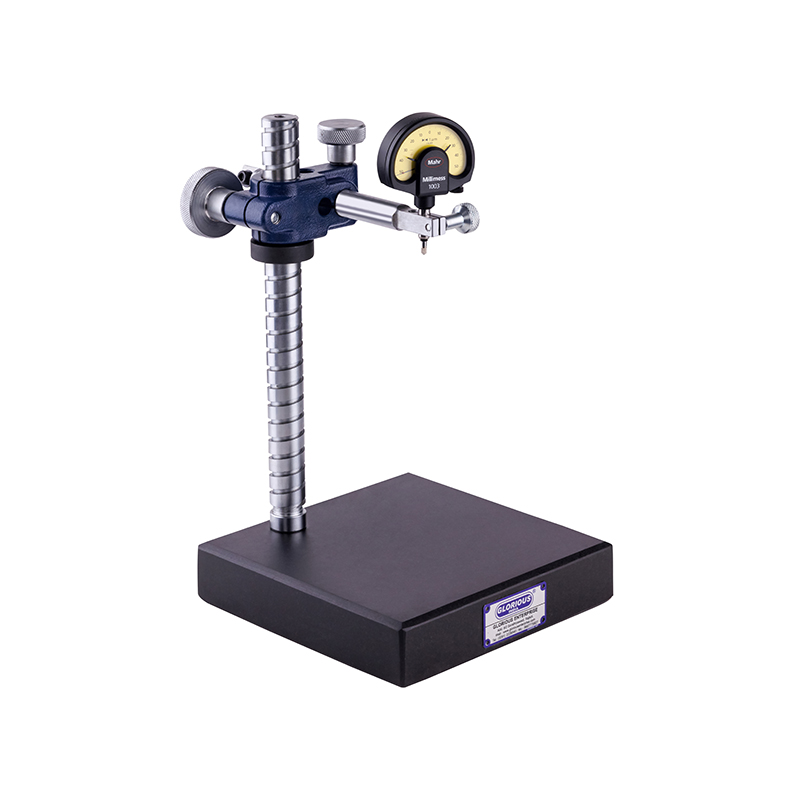

Granite Comparator Stand

We specialize in Granite Height Comparators, engineered for manufacturers and multinational corporations (MNCs) that prioritize precise height measurements.

Our equipment is customized to client specifications for accurate height and width measurements on surface plates, meeting laboratory standards.

These comparators provide meticulous dimensional accuracy, crucial for industries with strict quality standards and precise manufacturing requirements.

Customized sizes are available as per Client’s requirement.